ER70S-6 Drum Pack Welding Wire Features

ER70S-6,SG2,SG3,G3SI1,G4SI1 GMAW (MIG) welding alloy co2 gas shield welding wire

Designed for welding carbon steel and certain low-alloy steels also for non copper coated wire

Suitable for sustained elevated temperature service dual shield welding wire

Welding of various 500 N / mm2 tensile strength grade structural steel components

All position, include vertical down welding can choose mig welding volts amps and wire speed chart

Gray (post anodized) color

Standard: AWS A5.18 ER70S-6 | Chemical Composition % |

C | Mn | Si | Cu | S | P | Ni | Mo | Cr |

Grade ER70S-6 | 0.06~0.15 | 1.40~1.85 | 0.80~1.15 | ≤ 0.50 | ≤ 0.035 | ≤ 0.025 | ≤ 0.15 |

ER70S-6 Drum Pack Welding Wire Down Load

ER70S-6 Mig Welding Wire(SG2).pdf

ER70S-6 Mig Welding Wire(SG2).pdf

ER70S-6 Drum Pack Welding Wire Specifications

Mechanical Properties | Tensile Strength Mpa | Yield Strength Mpa | Elongation A (%) | Impact Value KV2 (J) -30℃ |

≥ 480 | ≥ 400 | ≥ 22 | ≥ 27 |

| Diameter(MM) | 0.8 | 1.0 | 1.2 | 1.6 |

MIG Welding | Welding Current ( A ) | 50 – 100 | 50 – 220 | 80 – 350 | 170 – 550 |

CO2Gas-flow ( L/min ) | 15 | 15 – 20 | 15 – 25 | 20 – 25 |

ER70S-6 Drum Pack Welding Wire video

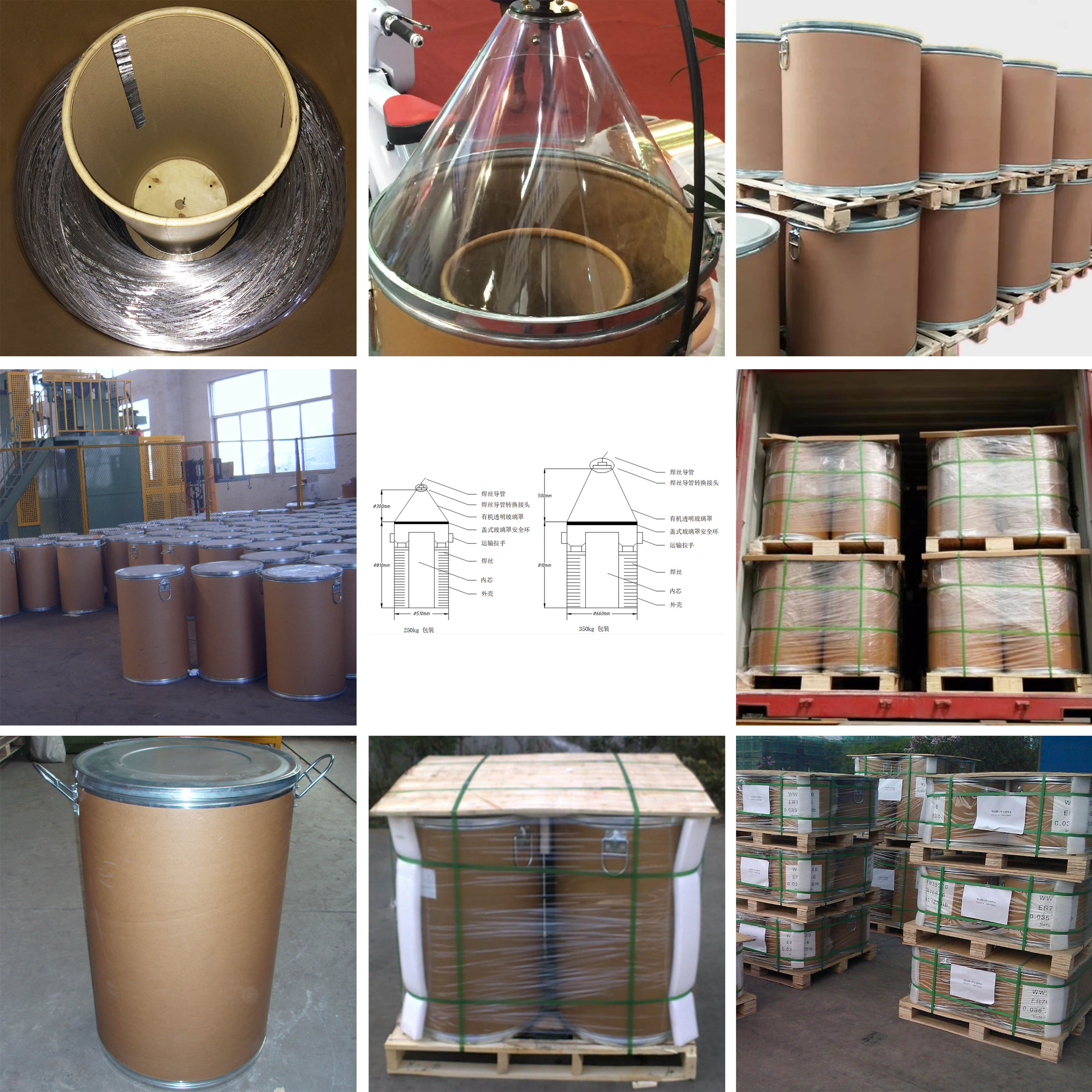

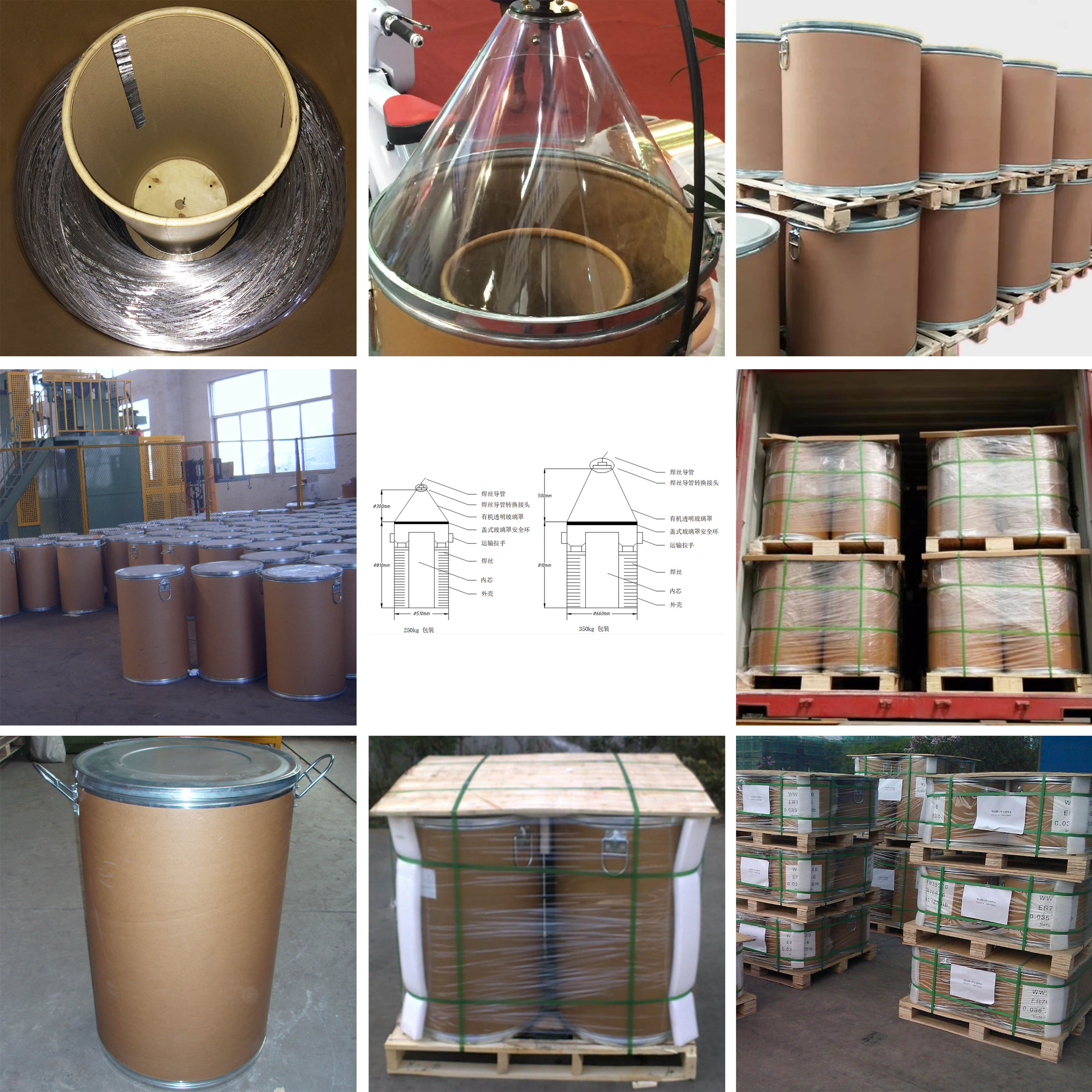

ER70S-6 Drum Pack Welding Wire Factory Show

ER70S-6 Drum Pack Welding Wire Application

035 mig welding wire,arc welding wire, wire feed welding can be used such as ships, heavy-duty machines, pressure vessel etc.

ER70S-6 Drum Pack Welding Wire Certification

ER70S-6 Drum Pack Welding Wire WHAT YOU GET

ER70S-6 Drum Pack Welding Wire/mig welding wire speed and voltage chart

Choose Your copper welding wire Size in mm: 0.8mm / 0.9mm / 1.0mm / 1.2mm/ 1.6mm/ 2.0mm

Choose Your solid welding wire Size in inch: 0.030 / 0.035 / 0.040 / 0.045/ 0.063/ 0.079 / 3/16 - 3/64

Choose Your SG2 Mig Wire Spool Weight(Package): 1kg / 5kg / 15kg / 250kg

Choose Your TIG Wire Size: 1.2mm/ 1.6mm/ 2.0mm/ 2.4mm/ 3.2mm/ 4.0mm/ 5.0mm

Choose Your laser welding wire tube Weight(Package): 5kg / 15kg / 1LB / 2LB / 4.5LB / 15.5LB / 33LB

ER70S-6 Drum Pack Welding Wire knowledge

wire mesh welding Winding Requirements

Electrodes on spools and in coils (including drums and reels) shall be wound so that kinks, waves,sharp bends, overlapping or wedging are not encountered,leaving the filler metal free to unwind without restriction.The outside end of the filler metal (the end with whichwelding is to begin) shall be identified so it can be readilylocated and shall be fastened to avoid unwinding.

The cast and helix of electrode in coils, spools,and drums, shall be such that the electrode will feed in an uninterrupted manner in automatic and semiautomatic equipment.

The cast and helix of solid filler metal on 4 in.[100 mm] spools shall be such that a specimen long enough to produce a single loop, when cut from the spool and laid unrestrained on a flat surface, will:

(a) form a circle not less than 4 in. [100 mm] nor more than 9 in. [230 mm] in diameter

(b) rise above the flat surface no more than 1/2 in. [13mm] at any location

The cast and helix of solid filler metal on all other package forms shall be such that a specimen long enough to produce a single loop, when cut from the package and laid unrestrained on a flat surface, will:

(a) form a circle not less than 12 in. [300 mm] for0.030 in. [0.8 mm] and smaller sizes; or not less than 15 in. [380 mm] for 0.035 in. [0.9 mm] and larger sizes

(b) rise above the flat surface no more than 1 in. [25mm] at any location

welding wire brush Filler Metal Identification

The product information and the precautionary information required in Section 23 for marking each package shall also appear on each coil, spool, and drum.

Coils without support shall have a tag containing this information securely attached to the filler metal at the inside end of the coil.

Coils with support shall have the information securely affixed in a prominent location on the support.

Spools shall have the information securely affixed in a prominent location on the outside of at least one flange of the spool.

Drums shall have the information securely affixed in a prominent location on the side of the drum.

hardfacing welding wire Packaging

Electrodes and rods shall be suitably packaged toensure against damage during shipment and storage under

normal conditions.

The following product information (as a minimum) shall be legibly marked so as to be visible from the outside of each unit package:

(a) AWS specification (year of issue may be excluded) and AWS classification numbers, along with any optional supplemental designators, if applicable

(b) Supplier's name and trade designation

(c) Size and net weight (see 6.1)

(d) Lot, control, or heat number

ER70S-6 Drum Pack Welding Wire WARNING

cast iron welding wire speed and voltage chart,Before use, read and understand the manufacturer's instructions, Material Safety Data Sheets (MSDSs), and your employer's safety practices.

wire spot welding have too many kinds ,Keep your head out of the fumes.Use enough ventilation, exhaust at the arc, or both, to keep fumes and gases away from your breathing zone and the general area.Wear correct eye, ear, and body protection.

ER70S-6 Drum Pack Welding Wire FAQ

ER70S-6 Mig Welding Wire 10 famous brand are which factory?

1:sanzhong, 2:giant, 3:bohler, 4:rural king, 5:lincoln, 6:hyundai, 7:blue demon, 8:esab, 9:Oxford, 10:golden bridge

ER70S-6 Mig Welding Wire supplier and factories or wholesale locates in such countries like?

China,America,Brazil,England,Russia,Poland,India,Pakistan,NewZealand,Korea,Australia,Dubai,Turkey,Indonesia,UAE.

How to choose a suitable SG2,SG3,G3SI1,G4SI1 welding wire?or what type of filler wire is best for tig welding for miller welding wire feeders?

The prefix “E” designates an electrode as in other specifications. The letters “ER” indicate that the filler metal may be used either as an electrode or a rod.For A5.18, the number 70 indicates the required minimum tensile strength, as a multiple of 1000 psi, of the weld metal in a test weld made in accordance with specification A5.18. Similarly, for A5.18M.

The letter “S” designates a solid electrode or rod.don't forget also can use non copper coated welding wire.

This specification includes filler metals clas�sified as ER70S-G [ER48S-G], E70C-G [E48C-G], andE70C-GS [E48C-GS]. ER80S-G.The “G” (multiple pass) or “GS”(single pass) indicates that the filler metal is of a “general”classification.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Български

Kurdî

Кыргызча

简体中文

简体中文