AWS E308L-16 Welding Electrode Features

used for welding ultra-low-carbon 022Cr19Ni10 and Cr19Ni10 stainless steel structures

used for 06Cr18Ni11Ti corrosion-resistant stainless steel structures whose working temperature is lower than 300°C

used in the manufacture of synthetic fiber, chemical fertilizer, oil and other equipments

Suitable for sustained elevated temperature service

All position, include vertical down welding

Gray - white(post anodized) color

Standard:AWS A5.4 AWS A5.4M | Chemical Composition % |

| C | Mn | Si | P | S | Ni | Cr | Mo | Cu |

Grade E308L-16 | ≤0.04 | 0.50~2.50 | ≤1.0 | ≤0.04 | ≤0.03 | 9.0~11.0 | 18.0~21.0 | ≤0.75 | ≤0.75 |

AWS E308L-16 Welding Electrode

AWS E308L-16 welding electrode.pdf

AWS E308L-16 welding electrode.pdf

AWS E308L-16 Welding Electrode Specifications

Specification ( MM ) | 1.6、2.0、2.4、3.2、4.0、5.0 |

Package | 5 kgs/plastic bag in a color box, 20kgs/carton, 1 ton in a pallet |

Mechanical Properties |

| Tensile Strength Mpa | Elongation % |

| Specification | ≥ 520 | ≥ 30 |

AWS E308L-16 Welding Electrode video

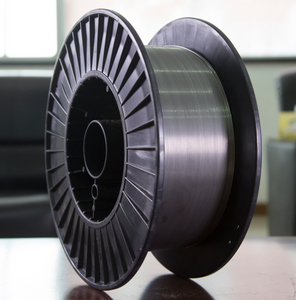

AWS E308L-16 Welding Electrode Show

AWS E308L-16 Welding Electrode Application

E308L-16 welding electrode is a kind of Titanium calcium type coating with ultra-low carbon Cr19Ni10 stainless steel electrode. Carbon content of deposited metal is less than or equal to 0.04%. The intergranular corrosion resistance is good. Excellent welding performance and heat resistance, high strength coating, the porosity resistance is good. AC/DC both can be applied.

AWS E308L-16 Welding Electrode Certification

AWS E308L-16 Welding Electrode WHAT YOU GET

E308L-16 Stainless Steel Welding Electrode

Choose Your stainless steel welding electrode Size in mm: 2.0mm / 2.4mm / 3.2mm / 4.0mm/ 5.0mm

Choose Your stainless steel welding electrode Weight(Package): 0.5kg / 1kg / 5kg /10kg /20kg

Choose Your wire feed welding Weight(Package): 5kg / 10kg / 1LB / 2LB / 4.5LB / 20LB

AWS E308L-16 Welding Electrode knowledge

stainless steel welding electrode Requirements

The filler metal shallbe wound so that kinks. waves.sharp bends.or wedging are not encountered leaving the filler metal free to unwind without restriction.The outside end of the filler metal(the end with which welding is to begin)shall be identified so that it can be readily located and shall be fastened to avoid unwinding.

The cast and helix of all filler metal in coils and spools shall be such that the filler metal will feed in an uninterrupted manner in automatic and semiautomatic equipment.

The cast and helix of drawn,solid filler metal on 4 in.[100mm]spools shall be such that a specimen long enough to produce a single loop,when cut from the spool and laid unrestrained on a flat surface, will do the following:

1. Form a circle not less than 2.5 in.[65 mm]nor more than 15 in [380mm] in diameter

2. Rise above the flat surface no more than 1/2 in.[13 mm] at any location.

stainless steel welding electrode Identification

The product information and the precautionaryinformation required in Clause 17Marking ofPackages, shall also appear on each coil and each spool.

Each bare straight filler rod shall be durably marked with identification traceable to the unique product type of the manufacturer or supplier. Suitable methods of identification could include stamping,coining,embossing, imprinting flag-tagging,or color coding.(If color coding is usedthe choice of color shall be as agreed between supplier and purchaser and the color shall be identified on the packaging.)When the AWS classification designation is used the“ER” may be omitted;for example“308L”for classification ER308L.Additional identification shall be as agreed upon between the purchaser and supplier

welding steel with stainless wire Packaging

Filler metal shall be suitably packaged to ensure against damage during shipment and storage under normal conditions.

The following product information (as a minimum of low temperature aluminum welding wire)

shall be legibly marked so as to be visible from the outside of each unit package:

(1) AWS specification and classification designation (year of issue may be excluded best wire for welding aluminum)

(2) Supplier's name and trade designation

(3) Size and net weight

(4) Lot, control, or heat number

AWS E308L-16 Welding Electrode WARNING

Oil, dirt and rust on the welding stainless with mild steel wire surface should be removed before welding. Surface impurities such as oil, rust and water should be thoroughly removed in the welding place, so as to prevent blowhole, crack and so on during welding. The surface of the groove and its surroundings should be polished with metallic gloss.

In order to obtain good mechanical properties of welding seam, suggest protect gas Ar+2%O2 and shield gas flow rate 20-25 L/min for gasless stainless steel welding wire. For TIG welding,suggest protect gas pure Ar and shield gas flow rate 8-15 L/min ,Arc length 1~3 mm; wind speed limit ≤ 1.0m/s,argon protection at the back of welding area .

In the stainless steel welding wire flux core process, the welding line energy directly affects the mechanical properties and crack resistance of weld metal, and should be paid more attention to.

The above welding methods, conditions and specifications are for reference only. Users should evaluate the welding process according to their own welding characteristics before using the welding stainless steel with mild steel wire for the formal product welding.

AWS E308L-16 Welding Electrode FAQ

mig welding wire stainless steel 10 famous brand are which factory?

1:sanzhong, 2:giant, 3:safra, 4:Hobart, 5:SAF, 6:ALCOTEC, 7:INDALCO, 8:HYUNDAI, 9:Oxford, 10:golden bridge

stainless steel welding wire flux core supplier and factories locates in such countries like?

China,America,Brazil,England,Russia,Poland,India,Pakistan,NewZealand,Korea,Australia,Dubai,Turkey,Indonesia,UAE.

stainless steel mig welding wire have how many types?

ER304,ER307Si,ER308,ER308L,ER308LSi,ER309,ER309L,ER309LSi,ER310,ER316,ER316L,ER316LSi,ER321,ER347,ER410,

ER430,ER2209,317l,E308LT1-1,E308L-16,E309L-16,E312-16,E316L-16,E4303

How to choose a suitable gasless mig welding stainless steel wire?or what type of filler wire is best for wire feed welding stainless steel?

The first two designators may be“ER”for solid wires that may be used as electrodes or rodsor they may be“EC’for composite cored or stranded wires;or they may be“EQ”for strip electrodes.

The three- or four-digit number,such as 308 in ER308,designates the nominal chemical composition of the filler metal.

ER307.The nominal composition(wt.%)of this classification is 21 Cr.9.5Ni.4 Mn.1 Mo.Filler metals .

ER308The nominal composition(wt.%)of this classification is 21 Cr10 Ni.Commercial specifications is most often used to weld base metals of similar composition, in particular, Type 304.

ER308Si.This classification is the same asER308except for the higher silicon content.

ER308H.This classification is the same as ER308.except that the allowable carbon content is used for welding 304H base metal.

ER308L.This classification is the same as ER308,except for the carbon content.Low carbon,is less than that of the niobium-stabilized alloys or Type 308H at elevated temperatures.

ER308LMo.This classification is used for welding ASTM CF3M stainless steel castings and matches the base metal with ER316L is desired.

ER309.The nominal composition(wt.%)of this classification is 24 Cr13 Ni.Filler metals.

304 and similar base metals where severe corrosion conditions exist requiring higher alloy weld metal.

ER309Si.This classification is the same as ER309,except for higher silicon content.

ER309L.This classification is the same as ER39,except for the carbon content.

ER309LS.This classification is the same as ER309Lexcent for higher sillicon content.

ER309Mo.This classification is the same as ER309except for the addition of 2.0 percent to 3.0 percent.

ER310.The nominal composition(wt.%)of this classification is 26.5 Cr,21 Ni.Filler metal of this classification is most often used to weld base metals of similar composition

ER312.The nominal composition(wt.%) of this classification is 30 Cr, 9 Ni.Filler metal of this classification was originally designed to weld cast alloys of similar composition.

ER316 weld metal may occur when the following three factors co-exist:

The presence of a continuous or semicontinuous network of ferrite in the weld metal microstructurel

ER316Si.This classification is the same as ER316,except for the higher silicon content.

ER316H.This filler metal is the same as ER316,except that the allowable carbon .

ER316L.This classification is the same as ER316.except for the carbon content.

ER316LSi.This classification is the same as ER316L except for the higher silicon content.

ER317.The nominal composition(wt.%) of this classification is 19.5 Cr14 Ni3.5 Mo, higher than ER316.

ER317LThis classification is the same as ER317except for the carbon content.

ER318This composition is identical to ER316,except for the addition of niobium.

ER321Thenominal composition(wt.%)of this classification is 19.5 Cr.9.5 Niwith titanium added.The titanium acts in the same way as niobium in Type 347.

ER347.The nominalcomposition(wt.%) of this classification is 20 Cr,10 Ni,with Nb added as a stabilizer.

ER347Si.This classification is the same as ER347,except for the higher silicon content.

ER409.This 12 Cr alloy(wt.%) differs from Tvpe 410 material because it has a ferritic microstructure.

ER410.This 12 Cralloy(wt.%) is an air-hardening steel.

ER410NiMo.The nominal composition(wt.%)of this classification is 12 Cr4.5 Ni.0.55 Mo.

ER430.This is a 16 Cr(wt.%) alloy.The composition is balanced by providing sufficient chromium to give adequate corrosion resistance for the usual applications.

ER439.This is an 18 Cr(wt.%) alloy that is stabilized with titanium.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Български

Kurdî

Кыргызча

简体中文

简体中文